MCi manufactures high-quality microwave components, systems and RF products for industrial drying, heating, food processing and material processing applications. From start-up companies with big ideas utilizing microwave technology, to well-established multinational food processing corporations – to industrial processors of wood, foam and textiles – MCi provides each with robust waveguide and coaxial components.

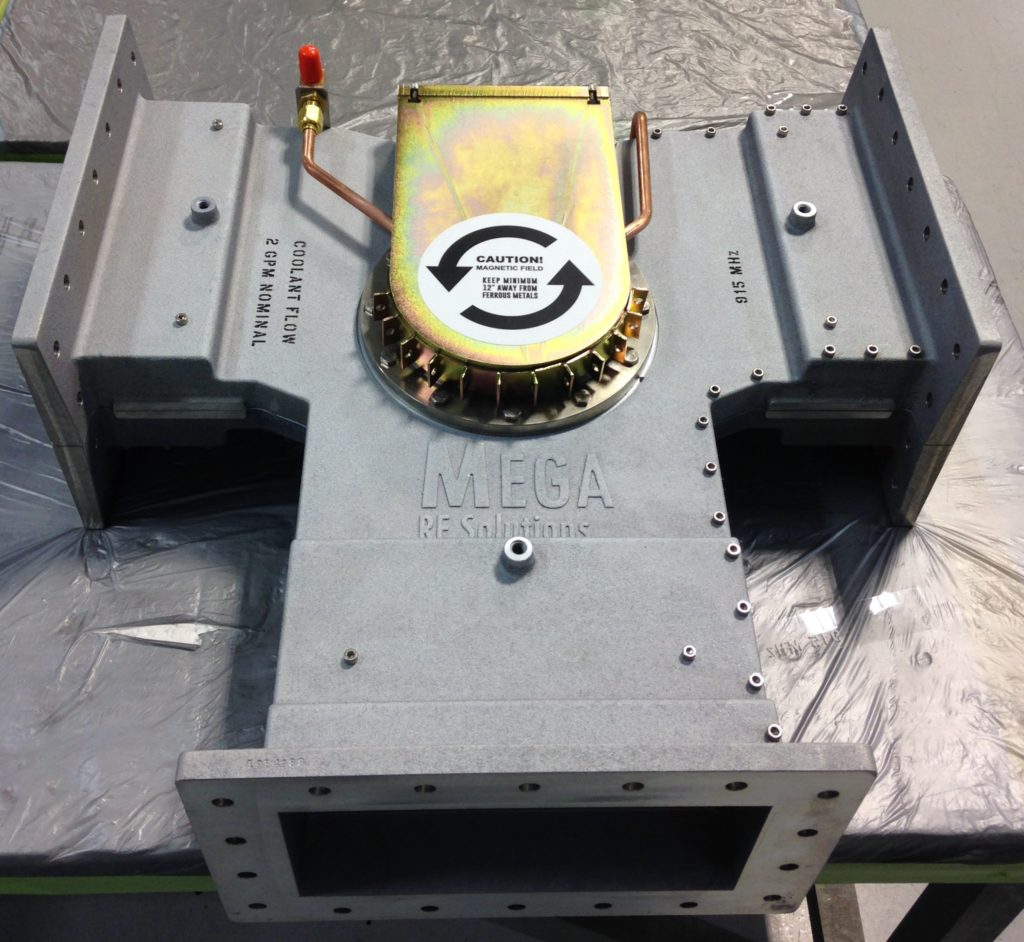

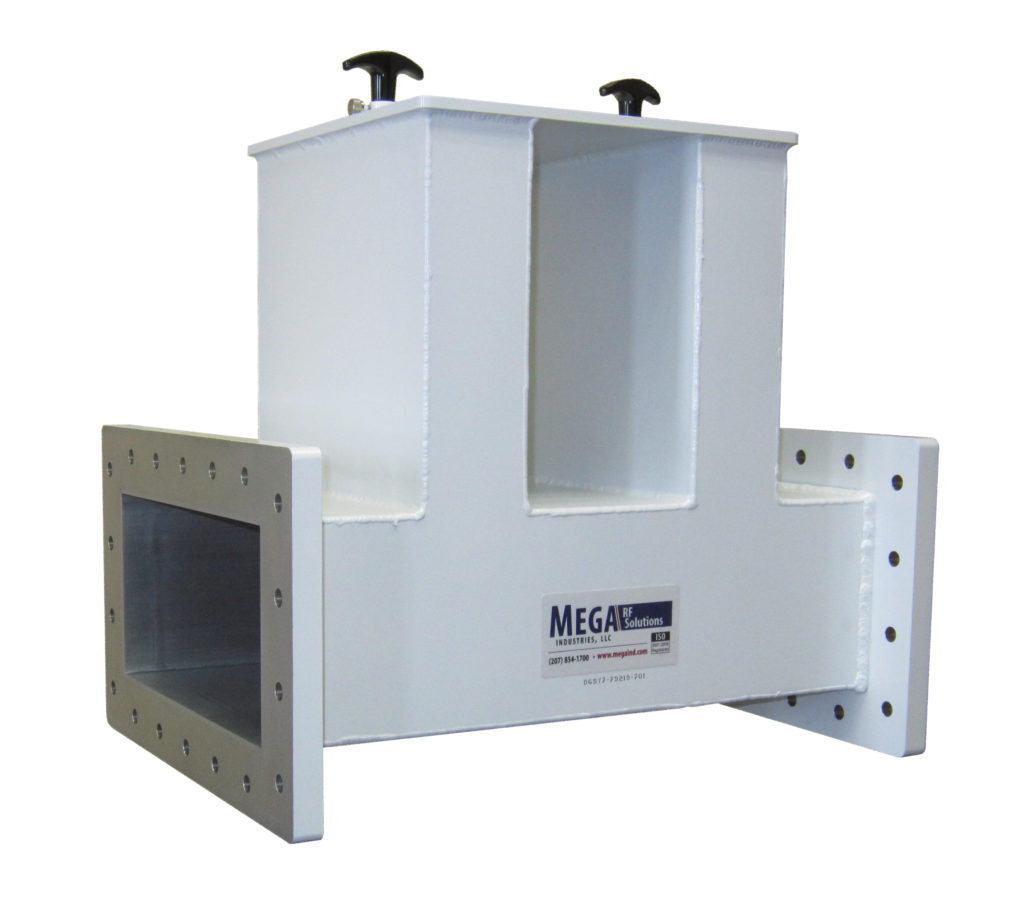

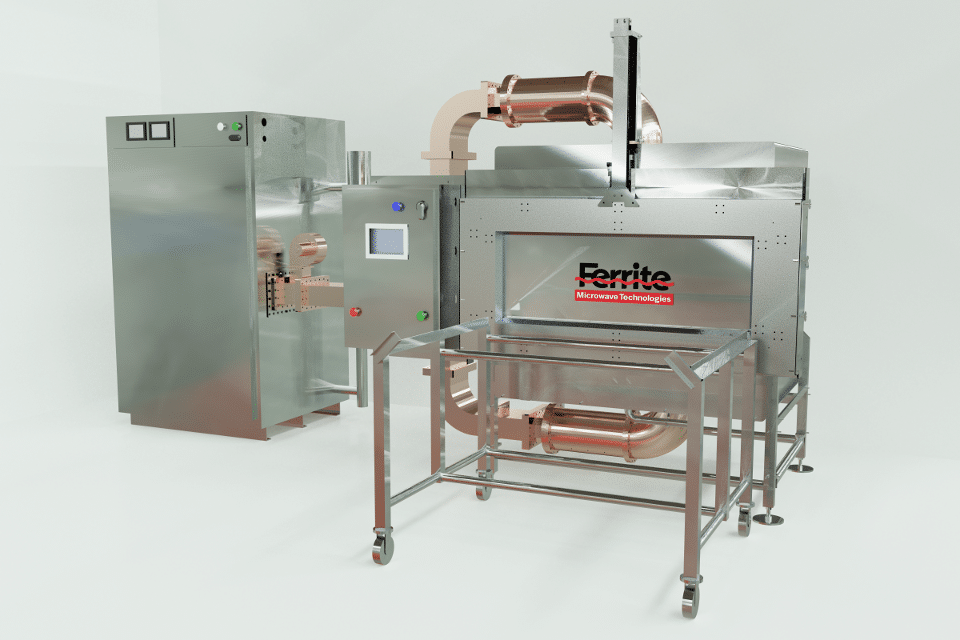

Our partners at Ferrite and Mega manufacture a full line of microwave components for 2450 MHz (2.45 GHz) and 915 MHz (WR975). Whether your system or assembly needs a waveguide tuner, pressure window or hybrid combiner – to a circulator, isolator or load – we’ll help you find a solution that fits your microwave system or industrial microwave project. Additionally, Ferrite Microwave Technologies has a complete line of systems for tempering, heating, drying and more.

Our industrial microwave heating and drying products are critical components in systems that process food, cure wood, dry materials, convert bio-waste, and beyond. There are countless material processes that rely on high-frequency electromagnetic energy – and reliability of the microwave components is vital for machinery to operate within certain parameters.

Our Capabilities

The industrial microwave heating and drying sector is driven by high volumes, price sensitivity, and short-lead times. As a result, most of our standard products are stocked, or available on short notice. Our products for industrial applications are tested and inspected under quality control procedures via our Quality Management System.

Our capabilities for industrial microwave heating & drying products include:

• Full line of WR284, WR340 and WR975 components

• Coaxial and Waveguide solutions for 896, 915, 922, 929 and 2450 MHz

• RF Experts: deep engineering knowledge of solutions for ISM bands

• Collaboration with Ferrite Microwave Technologies product line (systems and components)

• Full line of tempering, heating, drying, batch processing, bacon cooking systems

• Circulators, generators, magnetron tubes, hardware and replacement parts

• 75, 100 and 125 kW isolators for UHF processing systems

• Refurbish, repair, rebuild and upgrade services for system components

• RoHS and CE compliant components

• Standard & custom microwave components

• Client base: system OEM’s, plasma processors, oil and energy corporations, food and agriculture processors, industrial supply and materials (lumber, textiles, foam) producers, industrial (CVD) diamond manufacturers, plastics recyclers and beyond.

Industrial Microwave: Products

The team at Micro Communications has deep-rooted knowledge and experience with applying microwave technology to industrial heating, drying and processing applications. We design and manufacture ultra-reliable waveguide components to help regulate accurate and continuous performance.

Microwave Techniques: Industrial History & Growth

The history of Microwave Techniques involvement in the industrial microwave marketplace dates back to Ferrite Microwave Technologies legacy with Raytheon SMDO group.

In 1983, Ferrite Microwave Technologies was founded, an offspring of the Raytheon SMDO group. Originally, their sole focus was to support the demand for high-power components in the industrial and scientific markets. Soon enough, the demand for systems would push their product offerings into creating a systems division.

A few years later, in 1989 – Mega Industries was founded with a focus in providing microwave components and RF solutions to the scientific, commercial, military and industrial marketplaces.

In 1991, Mega acquired Microwave Techniques in Raymond to further cement their commitment to expanded manufacturing capabilities and component offerings. The Microwave Techniques name would return to the group, later in 2020.

By 1993, Ferrite began manufacturing microwave systems of their own to keep up with demand for components and systems in the industrial marketplace.

In 1997, Mega Industries moved to a facility in Gorham, Maine – which continues to expand to this day. The facility is the current site for the Microwave Techniques components division.

In 2003, Ferrite acquired the industrial microwave division of Amana. One year later, in 2004, FMT acquired RF technologies for their broadcast components and industrial processing systems.

In 2010, Mega opened the Industrial Microwave Oven Services (IMOS) division. The IMOS division served similar clients as Ferrite, and provided many of the components, services, maintenance and support that FMT’s industrial division still offers to this day.

In 2014, discussions began for a possible merger or acquisition of Ferrite, leading to a discontinuation of the Mega-IMOS division.

Later that year, Mega Industries integrated the components of Micro Communications Inc. (MCi) into the Mega portfolio in a 2014 acquisition.

In 2020, the Microwave Techniques group was reinstituted in a merger – covering the legacy product lines from Ferrite Microwave Technologies (FMT), Micro Communications Inc. (MCi), and Mega Industries.

As a combined entity, the Microwave Techniques group manufactures the widest line of components and systems for tempering, drying, heating and industrial processing. To learn more about our industrial microwave systems offerings, please visit Ferrite Microwave Technologies Systems Division website.

To learn more about our products, services, and support of microwave components and industrial systems – please contact us at sales@microwavetechniques.com. We look forward to partnering with you!